Google has not performed a legal analysis and makes no representation or warranty as to the accuracy of the list.) ( en Inventor John Louis Zoltan Tormasi Current Assignee (The listed assignees may be inaccurate. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.) Granted Application number CA2743835A Other languages French ( fr)

#Pushrod and slack adjuster pdf

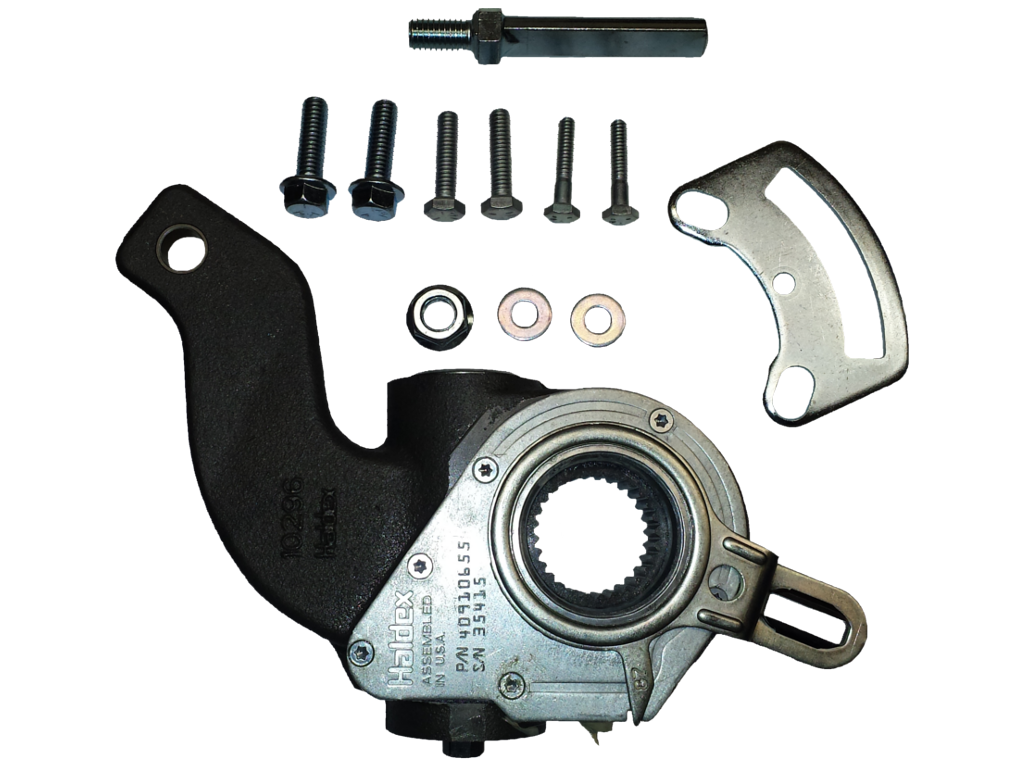

Google Patents Self-setting automatic slack adjuster with increased durabilityĭownload PDF Info Publication number CA2743835A1 CA2743835A1 CA2743835A CA2743835A CA2743835A1 CA 2743835 A1 CA2743835 A1 CA 2743835A1 CA 2743835 A CA2743835 A CA 2743835A CA 2743835 A CA2743835 A CA 2743835A CA 2743835 A1 CA2743835 A1 CA 2743835A1 Authority CA Canada Prior art keywords brake housing cam shaft slack adjuster way clutch Prior art date Legal status (The legal status is an assumption and is not a legal conclusion. Google Patents CA2743835A1 - Self-setting automatic slack adjuster with increased durability

#Pushrod and slack adjuster cracked

The manual adjustment of automatic slack adjusters is dangerous because it gives the vehicle operator a false sense of security about the effectiveness of the braking system.Ĭheck that brake chambers are not leaking, cracked or dented and are securely mounted.When pulled by hand, the brake rod should not move more than 1 inch (with the brakes released).The angle between the push rod and adjuster arm should be a little over 90 degrees when the brakes are released and not less than 90 degrees when the brakes are applied.Look for broken, loose or missing parts.Note: Be prepared to perform the same suspension components inspection on every axle (power unit and trailer, if equipped). (The mounts should be checked at each point where they are secured to the vehicle frame and axle(s))Ĭheck that shock absorbers are secure and that there are no leaks. Look for cracked or broken spring hangers, missing or damaged bushings and broken, loose or missing bolts, Ubolts or other axle mounting parts.Air ride suspension should be checked for damage and leaks.If vehicle is equipped with torsion bars, torque arms or other types of suspension components, check that they are not damaged and are mounted securely.Look for broken or distorted coil springs.Look for missing, shifted, cracked or broken leaf springs.

Check for power steering fluid leaks or damage to power steering hoses.Look for any missing nuts, bolts and cotter keys. Check that the steering box is securely mounted and not leaking.You can find it here: High Road 2.0 10.2 External Inspection (School Bus, Truck/Tractor) Steering Steering box/hoses: New! High Road 2.0! We have a new version of this program.

0 kommentar(er)

0 kommentar(er)